Artificial intelligence, IoT integration, and advanced robotics are transforming American manufacturing into a leaner, faster, and more competitive powerhouse.

By UNITEMFG Team • August 12, 2025 • 8 min read

Picture this: It's 3 AM in a bustling Ohio manufacturing facility. While most of us sleep, thousands of sensors pulse with data, machines whisper to each other in digital tongues, and AI algorithms orchestrate a symphony of production that would have seemed like science fiction just a decade ago. No human intervention needed—just pure, optimized efficiency running 24/7.

Welcome to the era of smart factories, where the American manufacturing renaissance isn't just about bringing jobs back home—it's about revolutionizing what "Made in USA" truly means.

The Factory That Thinks for Itself

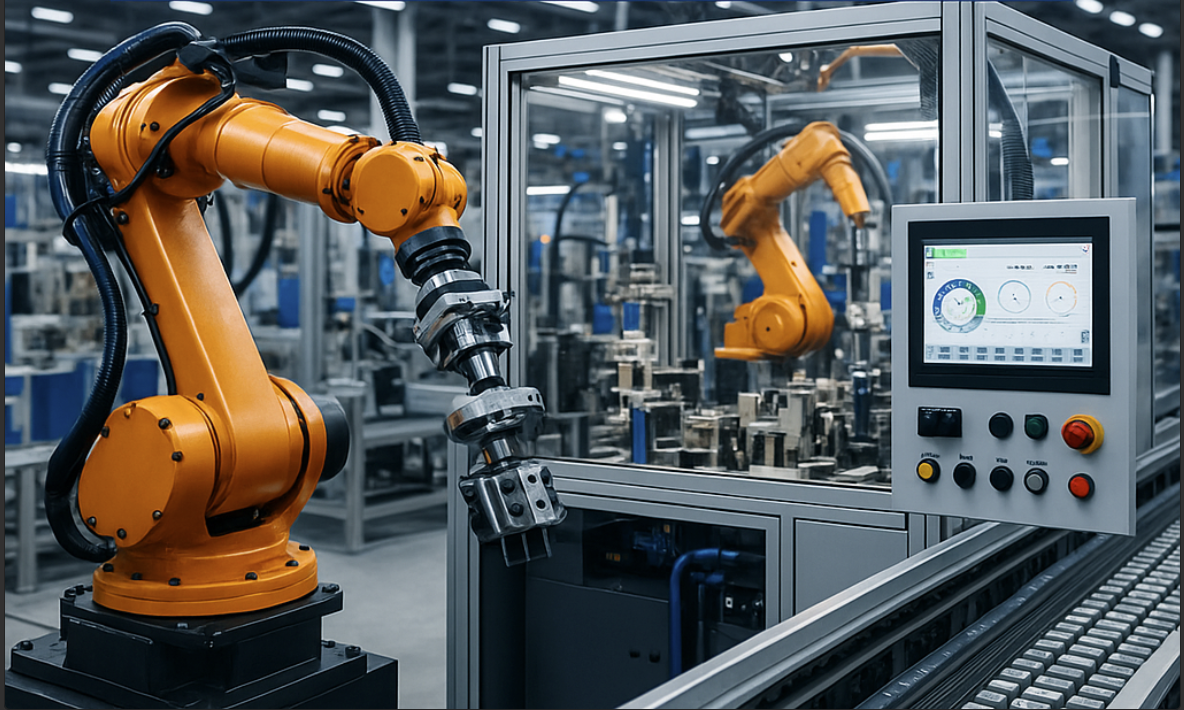

Forget everything you know about traditional manufacturing floors. Today's smart factories are living, breathing digital organisms that merge operational technology with AI-powered analytics, IoT sensor networks, and autonomous robotics. These aren't your grandfather's assembly lines—they're adaptive ecosystems that learn, predict, and evolve[1].

What sets them apart? Think of it as giving your factory a brain, nervous system, and reflexes all at once:

- The Brain: AI algorithms that make split-second decisions, optimizing production schedules faster than any human manager could dream

- The Nervous System: IoT sensors monitoring every heartbeat of machinery, detecting problems before they happen

- The Reflexes: Automated quality control that catches defects with superhuman precision, integrated seamlessly with ISO 9001 standards

The Numbers That Make CFOs Smile

Here's where it gets exciting for the bottom line. Smart manufacturing isn't just cool tech—it's a profit multiplier. We're talking about 25% efficiency gains and 40% fewer defects[2]. That's not incremental improvement; that's transformation.

Take the Texas manufacturer who implemented predictive maintenance AI last year. Their unplanned downtime dropped by 67%, saving them $2.3 million annually. Or the Ohio aerospace supplier whose smart quality control system caught microscopic flaws that human inspectors missed—preventing a potential recall that could have cost millions.

"The future of manufacturing isn't about cheap labor—it's about smart labor. We're not competing on cost anymore; we're competing on intelligence." — UNITEMFG Insight Report, 2025

The Tech Trinity Powering Tomorrow's Factories

1. Artificial Intelligence: The Master Orchestrator

Imagine having a genius operations manager who never sleeps, never takes breaks, and processes millions of data points per second. AI doesn't just schedule production—it anticipates supply chain disruptions, adjusts for weather patterns affecting logistics, and even predicts customer demand shifts based on social media trends[3].

One pharmaceutical manufacturer's AI system recently detected a subtle pattern in equipment vibrations that predicted a critical failure 37 days before it would have occurred. The preemptive fix? A $50 part. The prevented loss? $4.7 million in production delays.

2. Internet of Things: The All-Seeing Eye

Every bearing's temperature, every motor's vibration, every product's journey through the line—IoT sensors capture it all. But here's the kicker: they don't just collect data; they create a real-time digital twin of your entire operation. Managers can literally walk through a virtual replica of their factory floor from their laptop, spotting bottlenecks and inefficiencies invisible to the naked eye.

3. Collaborative Robotics: The Perfect Partners

Meet the "cobots"—robots designed not to replace workers but to make them superhuman. Picture a assembly line worker lifting 200-pound components effortlessly with robotic assistance, or a quality inspector whose cobot partner can detect defects at the microscopic level[4]. It's not man versus machine; it's man and machine, together, unstoppable.

Why American Manufacturing Can't Afford to Wait

Here's the uncomfortable truth: while we debate whether to adopt smart factory tech, our global competitors are already three steps ahead. But there's good news—the reshoring wave combined with recent supply chain wake-up calls has created a perfect storm of opportunity.

American manufacturers have something our overseas competitors don't: proximity to the world's largest consumer market, a skilled workforce ready to upskill, and an innovation ecosystem that's second to none. Smart factory technology isn't just about keeping up—it's about leaping ahead.

The manufacturers already featured in the UNITEMFG Directory aren't waiting for permission to innovate. They're installing sensors, training AI models, and watching their productivity soar. One precision machining company reported that after implementing smart systems, they could quote jobs 73% faster and deliver 40% quicker than their traditional competitors.

The 2030 Vision: Adapt or Become History

Industry analysts paint a stark picture: by 2030, 75% of U.S. manufacturers will have adopted smart factory technology[5]. The other 25%? They'll be competing for scraps in a market that's moved on without them.

But here's what the analysts don't tell you: the real winners won't just be the ones who adopt the technology—they'll be the ones who embrace it fully, integrating AI and automation into their company DNA. They'll be the manufacturers who see smart technology not as a cost center but as their competitive superpower.

Your Move: From Spectator to Smart Factory Pioneer

The smart factory revolution isn't coming—it's here, humming away in facilities across America, creating products with unprecedented precision and efficiency. The question isn't whether to join this revolution, but how quickly you can get started.

Ready to transform your operations from traditional to transformational? The UNITEMFG network connects forward-thinking manufacturers with the partners, technologies, and expertise needed to build the smart factories of tomorrow. Because in the race to manufacturing excellence, standing still is the same as falling behind.

Don't just manufacture products. Manufacture the future.

References

- Deloitte Insights. (2025). 2025 Smart Manufacturing Survey

- PwC. (2024). Next Manufacturing: Industry 4.0

- McKinsey & Company. (2024). Adopting AI in Manufacturing at Speed and Scale

- International Federation of Robotics. (2024). Top 5 Robot Trends 2024

- Gartner. (2024). Smart Factory Trends for Smart Manufacturing